Refurbishment of a water tube boiler in a food plant

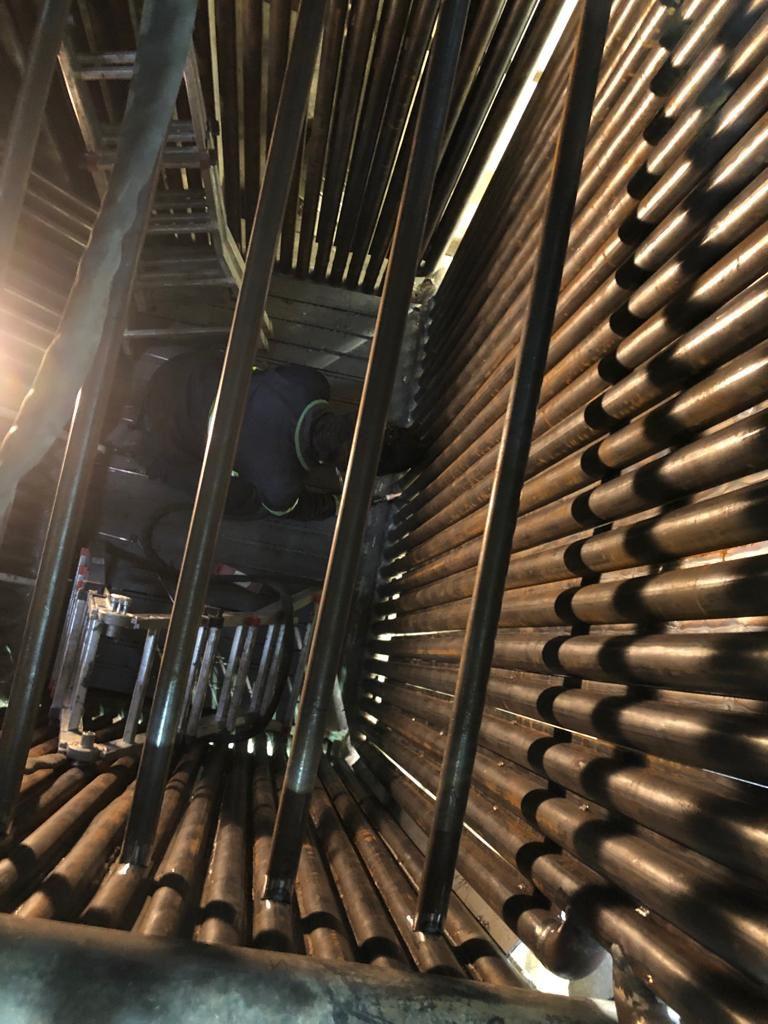

Reinva has carried out the refurbishment of a biomass water tube boiler in a food production plant, by changing the entire water tube section of the boiler, fueled by biomass, by the technicians of the company specialized in providing a complete service to energy processes and steam technology.

After the refurbishment of the biomass water tube boiler, the pressure equipment is fully operational in the food production factory. The aforementioned plant dedicates its activity to the manufacture of must concentrate (grape juice), subsequently used in a wide variety of products in the food, health or cosmetics sector. With this process of making juices for food, the must is available directly or mixed with other fruits. The transformation process consists of subjecting the juice to evaporation under vacuum, after which the concentrate is obtained.

The biomass steam boiler used in this food plant is of the water tube type and consumes grape pomace as fuel, although this type of fuel boiler can operate with different types of fuel such as olive pits and olive pomace and alperujo, coffee remains, industrial wood waste, dried fruit shells, sawdust, straw or others.

Characteristics of water tube boilers

Water-tube boilers are made up of a bundle of tubes through which water circulates and which is crossed externally by the flow of hot gases. In general, water-tube boilers are the most suitable for use at higher pressures and temperatures, and also for steam production from 50 T/h, since, although they are more sensitive to load and pressure fluctuations, they manage to vaporize water in a very short time.

Products and services for the food industry

In the food and beverage sector, Reinva’s equipment and services are present in a good number of combustion and steam processes, such as the custom design and manufacture of steam generators and hot gas generators, equipment for drying processes and optimization of thermal and steam processes. The company’s experience is manifested in dairy processing plants, bakery, soft drinks, dryers, packaging processes, cooking, pasteurization…

Reinva has multidisciplinary teams to carry out the reforms and repairs of industrial boilers, as well as pipes (steam, water, …), burners, economizers, etc., works completely approved in the welding procedures required by the manufacturers and certified by the various Authorized Control Organizations (OCA). Reinva’s extensive experience, with more than 40 years of history, allows it to have in-depth knowledge of the manufacturing procedures for boilers, economizers, tanks…, and therefore carry out repairs following the original standards.

Reinva’s services are aimed at comprehensively covering the challenges of engineering, installation, maintenance and repair of energy and steam installations. Its range of services generates added value for your company in the areas of energy saving, emission reduction and optimization of the production process.