Repair of a steam boiler for installation in Morocco

Reinva undertakes the repair of a steam boiler for its installation in Morocco in a plant dedicated to the manufacture of paper for packaging.

The repair of the steam boiler that the steam engineering company Reinva carries out in its workshop will allow the team to be reborn in full power and properly provide its services in its new location.

Among the services performed by Reinva are the necessary repairs to steam boilers, either at the client’s factory or in its own workshops, for which it provides a comprehensive service, from advice and solution of engineering problems to adaptation and modernization of equipment and commmissioing of boilers, among other equipment of thermal power plants and plants that use steam technology.

Steam boiler reborn in the workshop

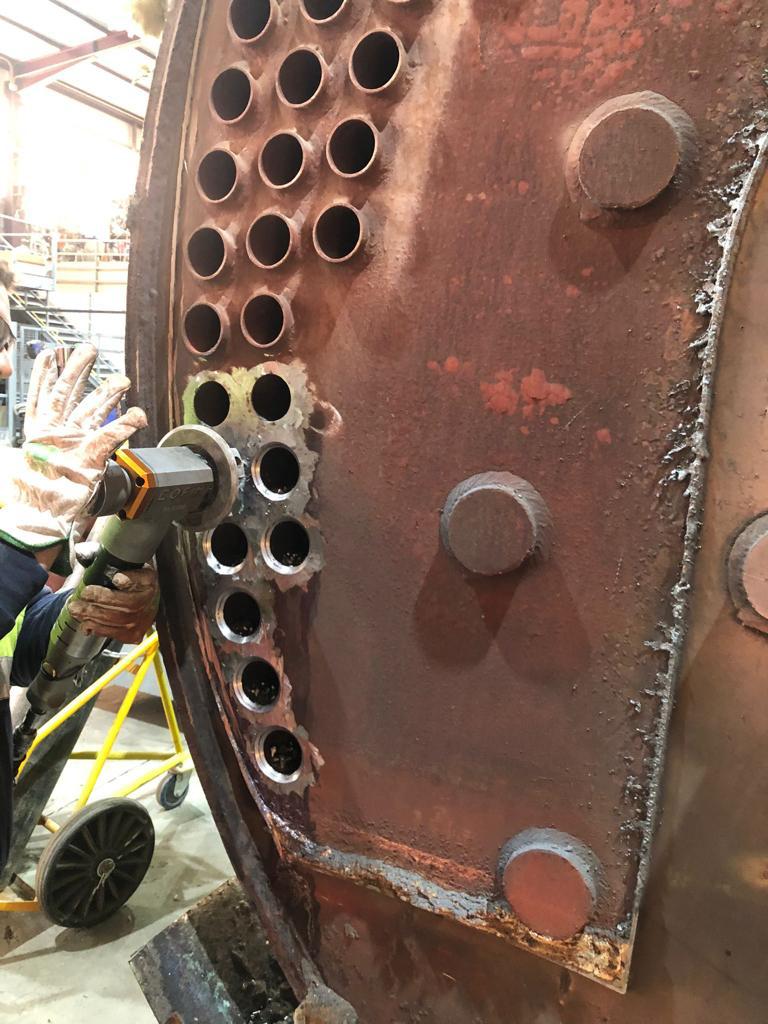

What is the repair of a steam boiler? Among the most frequent tasks in the boiler room repair process are the replacement of the components most subject to pressure, friction and wear (smoke tubes, tubular plates, refrigerated screens and fireplaces), as well as the repair and maintenance of the burners, in its aspect of gas regulation and analysis). Likewise, in the repairs section, Reinva deals with the supply of new boilers or second-hand boilers, the insulation of boilers and pipes, the repairs of exchangers, valves and pumps and the treatment of feed water to the boiler.

The phase prior to the repair of the steam boiler is the comprehensive analysis of the equipment to be repaired, through which the causes that have produced the deterioration of the equipment or the breakdown are identified, after which the company proposes solutions to correct said situations and prevent their recurrence.

In the images you can see the initial situation of the steam boiler, after several years of proper and competent use, and the repair process to which it is currently undergoing. We will offer you new images as the process progresses and gets underway at its final destination.

Reinva

Reinva’s technical team covers with its multidisciplinary services the needs of engineering, installation, maintenance, revamping and repair of industrial facilities and after-sales services to guarantee optimal service. These works add value to the production plant, since they lead to energy savings and an increase in production capacity, since they avoid unnecessary stops at the plant. They also provide elements of sustainability, through the change of fuel to other more sustainable fuels, and the incorporation of less polluting equipment.