Maintenance of large-power industrial boilers in the Levante steel sector

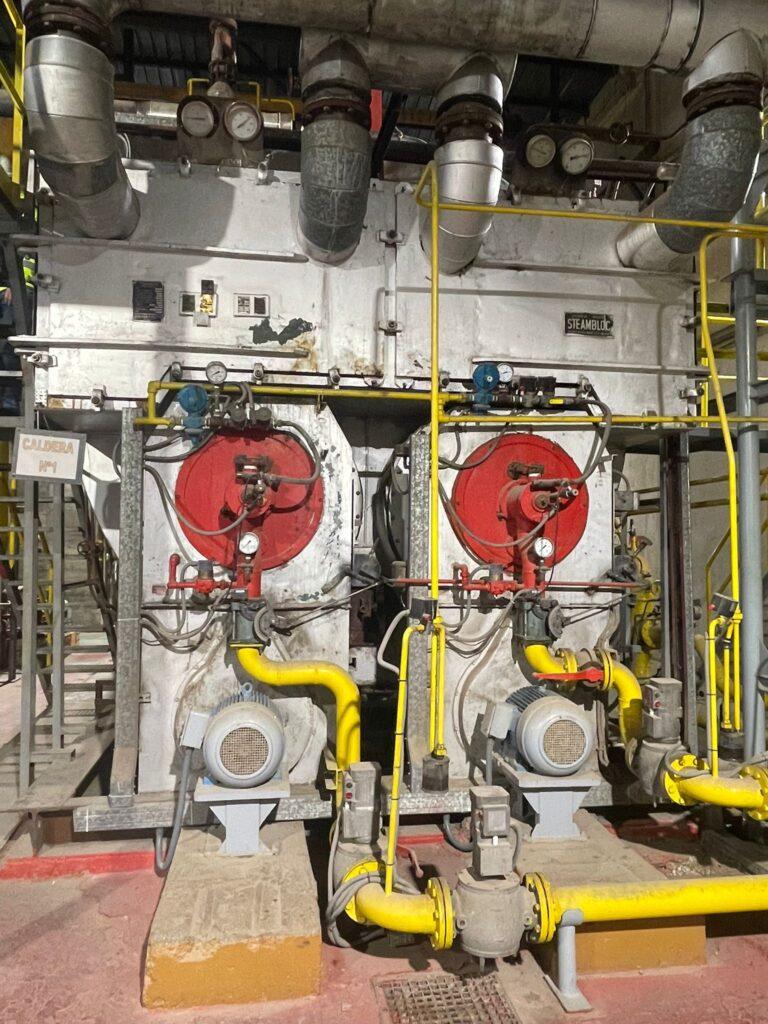

Reinva, a company specializing in the maintenance of high-power industrial boilers, is undertaking the maintenance process of a steel mill located in Levante.

The Spanish steel mill in which the works are carried out focuses its activity on the manufacture of flat steel products for various industrial sectors. It is currently immersed in a process of reducing its CO2 emissions, which is based on the optimization in the use of energy sources. To do this, the company invests in innovative and efficient technology in energy terms, which at the same time is ecologically and economically profitable.

The steel company’s process is part of effective energy management programs with the aim of reducing specific energy consumption in its processes, as well as optimizing manufacturing and design processes aimed at energy efficiency and adapting to best practices.

Maintenace of large-power industrial boilers

With more than 40 years of experience, Reinva is a company specializing in the maintenance of high-power industrial boilers. The company is in charge of everything necessary, from the sizing and installation of gas, water, steam pipes, electrical installation and the interconnection of all the elements of the room, as well as the automation and control and the supply and installation of the adequate water treatment for each plant to extend the life of the equipment and optimize energy savings.

Reinva’s activity has been focused on the area of engineering for the application of combustion technologies to industrial steam processes for more than 40 years. The company is focused on offering products and services aimed at optimizing the productivity of facilities that require heat and steam in industrial processes. In this sense, it is committed to sustainable development, supported by the engineering department, from which it develops projects aimed at contributing to the mitigation of climate change.

Among Reinva’s areas of activity is its specialization in the design, manufacturing, maintenance and after-sales services for industrial steam processes and combustion facilities, with the contribution of the necessary equipment and services.

Types of boiler maintenances

The maintenance process of industrial boilers is of paramount importance in order to achieve optimal operation of all equipment, especially boilers, in industrial process facilities and avoid incidents and unnecessary stoppages that affect plant production. Optimum tuning of company equipment maintains and strengthens the competitiveness of companies, especially at a difficult time due to the increase in energy costs and demanding climatic challenges.

- A-level maintenance

The periodicity of these level A inspections is annual. The boiler is inspected in accordance with the Pressure Equipment Regulations and requires the intervention of a certified maintenance company.

- B-level maintenace

The periodicity of the maintenance and inspection of level B is carried out on a triennial basis and requires the intervention of the OCA. In addition to what is indicated for Level A, a complete inspection of the documentation and condition of the boiler is carried out.

- C-level maintenance

The periodicity of these level C inspections occurs every six years. In addition to the requirements for Level B inspections, the hydrostatic test is carried out on industrial boilers.