Strategies for reducing energy demand in industry

Reinva proposes a series of strategies for reducing energy demand in the industry, which has become imperative to advance the objectives of reducing the cost of energy supply, minimizing the environmental impact and increasing energy security.

This is especially relevant since the second half of 2021, a period since which Europe has suffered an energy price crisis, which has a direct impact not only on domestic economies, but also on the competitiveness of companies and especially of the industry in global markets, as well as in medium and long-term economic growth.

This crisis situation has been aggravated by the geopolitical conflicts in Eastern Europe, which has driven up the price of natural gas in the main European markets and the price of electricity in wholesale markets. Within this framework, Europe must do facing challenges of great importance in terms of energy to achieve its economic, social and environmental objectives.

The challenges take shape in energy dependence on imports, the volatility of hydrocarbon prices, climate change, increased demand and obstacles to the internal energy market, but also in achieving high efficiency and performance of equipment and facilities.

Energy demand in industry

According to data from the Basque Energy Agency (EVE) report “Guide to good practices for reducing energy demand in industry”, the sector with the highest final energy consumption in the Basque Country is transportation (41.6 %), followed by industry (37.2%) in the share of total consumption.

The final energy consumption of the Basque industrial sector reached a value of 1,830 ktoe in 2021, with an increase of 19.6% compared to the previous year. Basque industry increased consumption from all energy sources. Thus, electricity consumption increased by 15.8%; that of petroleum derivatives, increased by 15.6%; that of natural gas, by 22.6%; that of coal, by 53.6%; and the consumption of renewable energies, by 22.9%.

The EVE recognizes that the industry has been one of the sectors that has had the most impact on actions aimed at improving energy efficiency as it is a sector that is intensive in energy consumption. However, it considers that the industry continues to be a strategic sector of action, with a high potential for reducing final energy consumption and carbon dioxide emissions. The entity recommends the incorporation of the best available technologies in equipment and processes, energy efficiency and the implementation of energy management systems as the way forward.

Reduction of greenhouse gas emissions

In turn, the report of the Basque Institute of Competitiveness Orkestra “Energy efficiency in the industrial sector” (Jorge Fernández Gómez) of 2021 pointed out the need to achieve ambitious objectives in terms of reducing greenhouse gas emissions worldwide in the medium term, which made energy efficiency the protagonist and key lever to achieve a sustainable energy system in the long term and, in particular, to advance the decarbonization of the industrial sector.

Thus, it seems that the decarbonization of the industrial sector requires a general increase in energy efficiency, an increase in the penetration of renewable energies and the development of new clean technologies (hydrogen technologies, synthetic fuels, bioenergy, advanced electric batteries and solutions capture, storage and utilization of CO2).

Strategies: Investment in energy efficiency

Investments in energy efficiency in the industrial sector can focus on the replacement or adaptation of equipment, the development of new production and operational processes, new energy sources or better use of materials in production processes. In all of these areas, there are mature and commercialized technologies and technological solutions that can facilitate the capture of significant levels of energy efficiency gains.

Efficiency in the field of energy refers to the relationship between the results obtained and the energy resources used to achieve them. The concept of energy efficiency refers to the ability to obtain the best results in any activity using the smallest possible amount of energy resources. In this way, energy efficiency allows us to reduce the consumption of any type of energy and at the same time reduce the possible environmental impacts associated with it.

Saving energy in companies is essential for them to be sustainable. Improving energy efficiency will result in economic savings and is an essential condition for sustainable development.

Contributions of energy efficiency in industry

- Productivity increase. Energy efficiency consists of maintaining productivity while reducing the energy consumed to carry out the same industrial processes. In fact, if executed correctly, the objective is that, with improved performance, productivity increases, reducing unnecessary expenses. The greatest energy consumption is located in industrial, operational and productive processes. Its optimization is key to trying to reduce consumption as much as possible without lowering the level of productivity.

- Competitiviness. Spending less on the energy bill implies that this resource can be invested in optimizing the industrial process and adopting better technologies to be more competitive.

- Economic advantages. La Energy efficiency also includes energy management that allows all applied processes and solutions to be monitored so that they reach their greatest potential at all times and not waste money or time on late repairs or reduced efficiency.eficiencia energética también contempla la gestión energética que permite monitorizar todos los procesos y soluciones aplicadas para que alcancen su mayor potencial en todo momento y no perder dinero ni tiempo en su reparación tardía o en su reducción de la eficiencia.

Strategies for reducing energy demand in industry

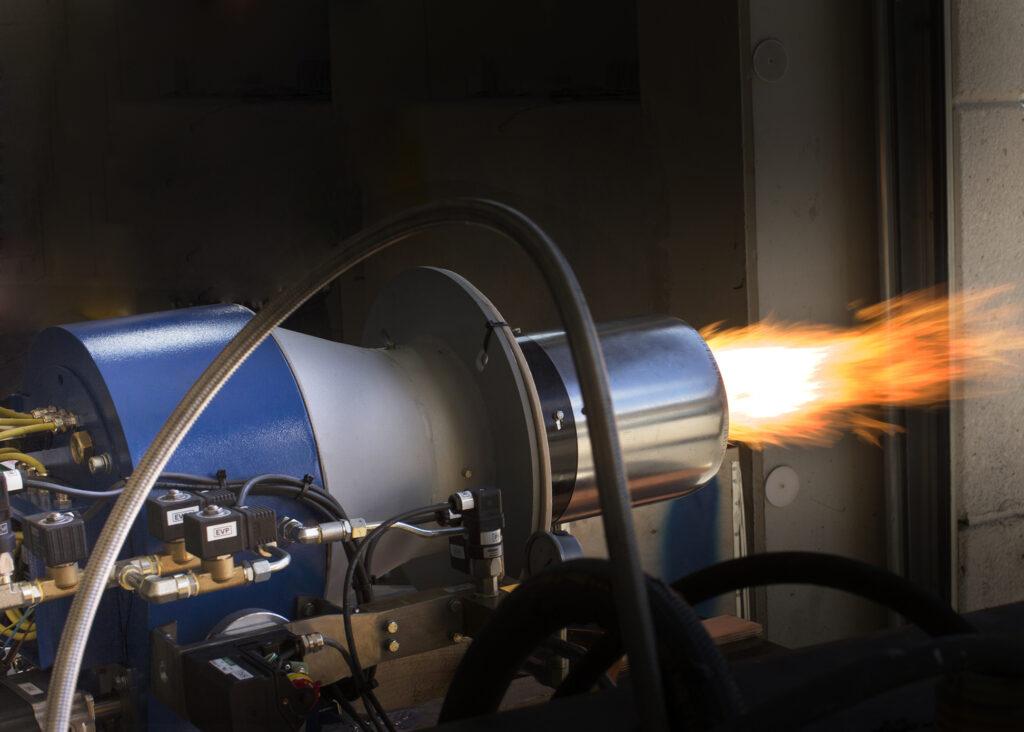

Among the energy demand reduction strategies in the industry that can offer the greatest profitability according to the EVE report are comprehensive process control system technologies and interval counters, which facilitate the optimization of energy use, as well as gas monitoring systems and high efficiency burners. Investments in energy management systems and equipment that optimize combustion processes, heat utilization and gas recovery are also profitable.

Mature technological solutions that improve energy efficiency:

- Comprehensive process control system

- Optimization of energy use

- High efficiency burners

- Energy management systems

- Equipment that optimizes the combustion processes

- Hot gas recovery

With the aim of incorporating these technologies that offer greater profitability, the report proposes making investments in energy efficiency in the industry. At Reinva, an engineering company specialized in providing a complete service to the energy and steam technology processes required by industrial plants, we are in charge of carrying out the design and execution of customized projects and accompany our clients in their engineering needs, supply, energy audit and energy efficiency, installation, maintenance, repair and spare parts.

- Replacement or adaptation of equipment

- Development of new production processes and equipment operation

- Diversification of energy sources, including optimization by changing fuel or the use of alternative energies

- Better use of materials in production processes

- Insulation of facilities and pipes to avoid thermal losses

- Replacing fuels with more efficient or economical ones